Category

3 Axles Strong Hydraulic Jacking Front Lifting Rear Dumping Tipper Van Semi Trailer

3 Axles Strong Hydraulic Jacking Front Lifting Rear Dumping Tipper Van Semi Trailer Specifications Our Products Characte

Basic Info

| Model NO. | ZCZ9400ZZXHJD |

| Material | Steel |

| Condition | New |

| Rated Weight | 31500kgs |

| Axles′ Quantity | 3PCS |

| Axle Base | 6070+1310+1310mm |

| Van Length | 103, 009, 800mm |

| Van Wide | 2270mm |

| Van Height | 600mm |

| Tyre Quantity | 12PCS |

| Q′ty of The Steel Plate Spring | -/7/7/7, -/10/10/10, -/12/12/12PCS |

| Axle Load | 23980kgs |

| Transport Package | Whole Trailer Waxed, Sea Water-Proof Paint |

| Specification | CCC ISO9001 SGS |

| Trademark | CHHGC |

| Origin | China |

| Production Capacity | 5000 PCS Per Month |

Product Description

3 Axles Strong Hydraulic Jacking Front Lifting Rear Dumping Tipper Van Semi TrailerSpecifications

| Item No. | ZCZ9400ZZXHJD | Batch | 245 |

| Brand | CIMC | Type | Dump semi trailer |

| Rated weight | 31500 | Total Weight(kg) | 39980 |

| Curb weight(kg) | 8480 | Axles' Quantity | 3 |

| Axle base(mm) | 6070+1310+1310 | Axle load | 23980(3 axles installed side by side) |

| Q'ty of the steel plate spring | -/7/7/7,-/10/10/10,-/12/12/12 | Tyre Quantity | 12 |

| Tyre size | 11.00R20 12PR,12R22.5 12PR,11.00-20 12PR | Approach/Departure angle | -/20 |

| Front/rear suspension(mm) | -/1550 | Wheel base(mm) | 1840/1840/1840,1820/1820/1820 |

| Overall length | 11340 | Overall wide | 2500 |

| Overall height | 3950 | Van length | 103,009,800 |

| Van wide | 2270 | Van height | 600 |

| Max loading of the saddle | 16000 |

Our Products

Characteristics

Subframe structure:

The subframe od the central-positioned dump truck is formed by snap-fit from high strength steel t ensure effectively the strength. The lower hinged joint for cylinder and tension arm is of integral structure to prevent the deviation. The subframe longitudinal beams for front-positioned dump truck adopts high strength steel rectangular tube to effectively promote the bearing capacity of the whole vehicle and reduce the cracking symptom due to welding factors. The widened rear tilting seat can greatly promote the stability, safety, and reliability during the traveling and lifting of the while vehicle.

Rear body structure:

The rear body adopts fully welded horizontal and vertical ribs and triangular box is added depending on the regional characteristics to effectively improve the impact resistance of the rear body.

Door operating mechanism:

This mechanism is in multiple types, including tie rod type, steel hinge type, pneumatically operated type, and hydraulically operated type, of which the tie rod and pneumatically operated type are our patented products to realize automatic open and close of the rear body and ensure safe and reliable dumping.

Lifting alarm:

The alarm will buzz while the vehicle is being lifted, in order to eliminate potential safety hazard.

Baseplate damping structure:

The new two-layer baseplate with rubber cushion in the middle is adopted to damp the impact force onto the baseplate by means of the damping function of rubber, which effectively improve the service life and practicability of the whole vehicle.

Anti-adhesion structure of dump body:

For the dump trucks for transport of wet and sticky cargo, the adhesion of cargo and low dumping rate will lead to extremely low operation efficiency. We developed one synthetic resin plate with good slipping performance, which is assed to the four walls and baseplate of the dump body to effectively improve the adhesion symptom of cargo and promote the transport efficiency.

Remark:

The above trailer is just one product we producing according to customer's requirements.

As the requirements of the customers in different countries are different, we can supply the customer any type trailer he need, based on our 60 years' experience of producing trailers.

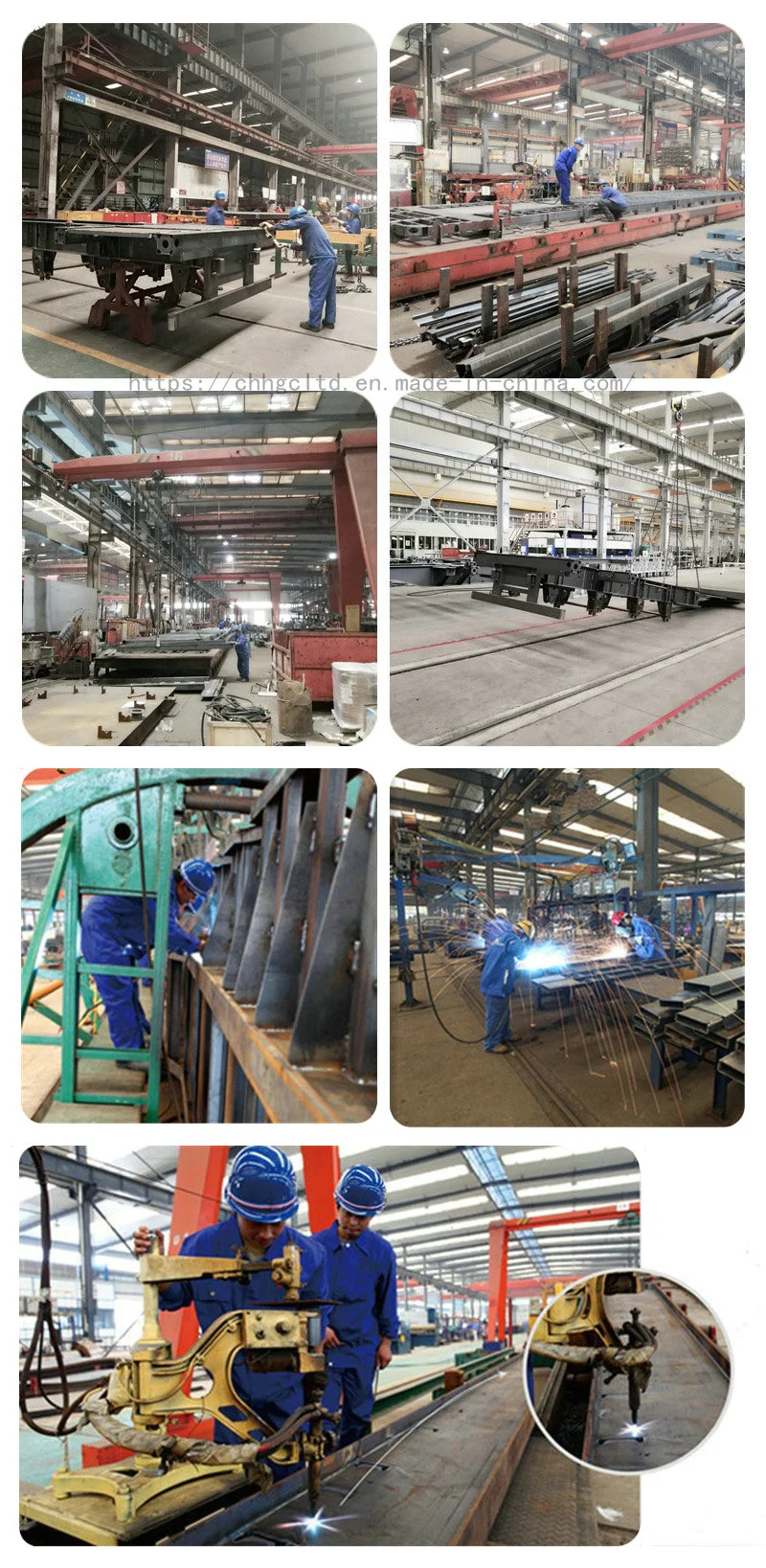

Workshop

Why us?

Design:

The senior engineering technicians, who boast extensive practice experiences, frequently visited and investigated the mines and working sites to master the operation and transport environments of various vehicles in all regions nationwide. The 3-dimensional software design is applied and the finite element analysis and optimization by topological technology are introduced to realize customized manufacturing and ease the use.

Materials:

The steel plates adopt the quality materials from domestic large steel works to guarantee the material performance, with plus thickness deviation and sufficient thickness.

Parts:

Five major hydraulic adopt the specially customizes products from domestic renowned brands and the sealing units adopt the products from world's renowned brands, featuring durability and safety guarantee.

Production:

There are many highly skilled personnel, the critical quality points are operated by professionally experienced senior technicians mand all operators are trained before assuming working post. The streamline and standardized operations and fine techniques guarantee the quality.

Appearance:

All parts are shot blasted, all assemblies are painted before assembly, and the body plates are acid picked and phosphating treated to greatly improve paint adhesion and ensure shining and lasting paint.

Our Advantages

1- With well experienced semi trailer production company to offer high quality and competitive prices semi trailer to our worldwide valuable customers.

2- An professional team which is experienced with international market and has strong technical capability to customized cost effective.

3- Sell well in the international markets, such as African market ( Sudan, Angola, Zimbabwe, Liberia, Djibouti, Congo, Kenya, Ghana ect. ), Middle East, South Asia and South-America market.

4- 2 Years Guarantee for all the the beam of trailers, timely shipment.

Quality Control

1- For Each trailer, we should do the testing and inspect the quality.

2- We give inspection certificate according to customer demand for every trailer which given by an independent third party certification company.

3- We provide out-standing quality assurance.

4- No any quality complaints for 9 years.

Perfect Service & Support

1- Whenever reliability, safety and economic is needed, there is a a solution. CHHGC provides the best possible quality semi trailers to worldwide valuable customers.

2- With a full range of trailer spate parts support, spare parts supplying within 3 days.

3- Seriously consider customer's requirements, and welcome different cooperation mode.

4- Provide professional trailer drawing.

5- Considerate after-sales service & product maintenance.

FAQ

1. Can i have samples of this type of trailer to test the quality?

Yes, you can buy any samples to test the quality, our MOQ is 1 set.

2. What's the delivery time and can you lower the price?

It depends on your order. The delivery time is within 15 workdays after we received your prepayment. If you have place an order of large quantities, then, of course, the price can be lowered.

3. Can i customize the painting and the logo?

Yes, we offer customized logo for any type.

4. What's the payment method?

TT 30% as Deposit, Balance Before shipment by TT or L/C at sight.